Nouvelles de l'industrie

Pourquoi le moule SMC peut - il brûler tout le cercle de la salle de bain?

Clean and dry

SMC mold material molecular structure is tight, the surface is smooth, not easy to residual stains, no dead corner structure, especially easy to clean up.

At the same time in the overall bathroom, SMC molded waterproof disc, with 1% water gradient, drainage quickly, the ground is not easy to water.

Affectful and durable

Different from the traditional ceramic tile, plate and other materials, SMC mold material is widely used in the overall bathroom industry, carrier rocket inner shell, aircraft cabin and other aerospace manufacturing fields, it is also indispensable. After professional product stain test, it is confirmed that SMC material can recover up to 90%, with super durability.

Insulation insulation

SMC mould has very low thermal conductivity, so heat insulation in winter, heat insulation in summer, excellent heat insulation performance. Matching body temperature, comfortable touch.

Affectant green environmental protection

SMC mold material is made up of unsaturated polyester resin, low shrinkage agent, filler, reinforcement material, curing agent and so on. It is a new type of thermosetting molding material. The above materials can be used as tableware materials in developed countries, low formaldehyde release, no radioactive elements, very environmental protection.

Just on paper material, not enough to become the circle of mouth - to - mouth classic. SMC mold materials are really popular, ultimately because it is really good to use.

The integral bathroom is an integral frame consisting of an integrated waterproof chassis wall panel and top plate, complete with bathtub, sink, faucet, shower, tile and other bathroom accessories. A separate sanitary unit that can be used in a limited space for multiple functions such as washing, bathing, grooming and toilet. Mold is the most important tool for the production of integral bathroom products. The quality of mold directly affects the quality and cost of products. Accordingly, the design of mold and manufacture already became in contemporary bathroom very important one annulus.

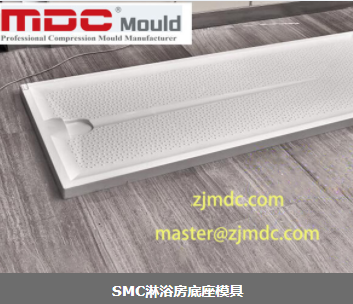

Bathroom moulds are usually equipped with a press to form a ceiling or shower base in one go. The SMC bathroom product can be assembled seamlessly with the wall without any traditional waterproofing. This large waterproof shower tray has high requirements on molds and production equipment. SMC waterproof chassis mold production requires more than 2000 tons of hydraulic press. As a supplier of sanitary ware mould, Dacheng has developed laundry trough mould, shower room base mould, wash basin mould and bathtub mould.